Fleet electrification planning is a huge task. An electric fleet requires completely different operations, tools, infrastructure, and strategy than an ICE fleet. It is a paradigm shift from how your fleet has always operated before. Naturally, this is an intimidating project. So, how do you get started on your fleet electrification roadmap and start taking meaningful action towards a profitable EV fleet conversion?

After reading this article, you will learn why and how your fleet operations will change with electrification, how to know which electric fleet vehicles to buy, how to optimize your variable costs and TCO (Total Cost of Ownership), and get the critical data for planning and operating a successful fleet.

Want to start planning with actionable data right now? Simulate what any route will look like with an electric van. Choose from different models and plot your route in just one minute.

Do I need to electrify my fleet?

The short answer, yes. The urgency depends on your geography, but bans and regulations on ICE (internal combustion engine) commercial vehicles are soon coming into effect around the world. Some of these include the EU’s proposed ban on the sale of ICE cars and SUVs by 2035, bans on ICE commercial vehicles in city centers like Amsterdam and Madrid, and the US government’s plan to phase out ICE vehicles entirely from their fleet by 2035-2040.

The transition to an electric fleet means major logistical, financial, and infrastructure changes to the way that you will operate your fleet that should not be underestimated. Here’s what you should expect.

Why will my fleet’s operations change when I convert to EV?

Electric vehicle fleet management is very different from ICE fleet management. There are two primary changes that drive the change to your operations; charge time and energy management. This is because charging a vehicle takes much longer than refuelling and electricity management is far more complex than fuel.

How will charge time impact my operations?

It takes much longer to charge an EV than it does to refuel a petrol or diesel vehicle, adding hours of time into schedules for charging that previously weren’t there. This makes deciding when and how much to charge extremely important for maintaining efficiency.

Additionally, not all charging or chargers are made equal. Between level 1, 2, and 3 charging, the speed you are able to charge varies a lot.

Charger types explained:

Level 1 charging - residential 120V AC outlets (40-50+ hrs to charge a car to 80%)

Level 2 charging - traditional EV chargers (4-10 hrs to charge a car to 80%)

Level 3 charging - “fast charging” (20 mins - 1 hr to charge a car to 80%).

These estimates are still very general as charge times vary greatly by vehicle. You need to understand the charge times for each of your vehicles in order to plan your schedules accordingly.

You also need to consider your charge curves. A charge curve is the speed at which a battery charges. Generally, the first 20-40% charge of a battery happens much quicker than the next 60-80%, depending on the vehicle. As a result, charging to full every time for every vehicle is almost certainly not the most time-efficient method. This means you may want to consider a just-in-time charge plan to minimize your time spent charging and maximize your time spent on routes.

Just-in-time charge plan: A fleet charging schedule optimizing for charge curves by only charging the necessary amount to complete a given trip.

How is managing electricity different from fuel?

The electricity game is much different from petrol and diesel so it requires a new way of looking at it. Simply keeping your operations the same, but swapping fuel for electricity won’t lead to success. A successful fleet electrification plan treats electricity as a whole new operational model.

Managing electricity is all about matching supply and demand and storing electricity is extremely expensive and difficult. As a result, energy access and prices are unpredictable and constantly changing. The level of difficulty to manage this will depend on how centralized or decentralized your charge strategy is. We will explain these concepts later on.

Energy is far more volatile than fuel

Fuel prices have been volatile lately and you have likely seen the impacts of this on your operations. But, electricity price fluctuation is on a whole other level.

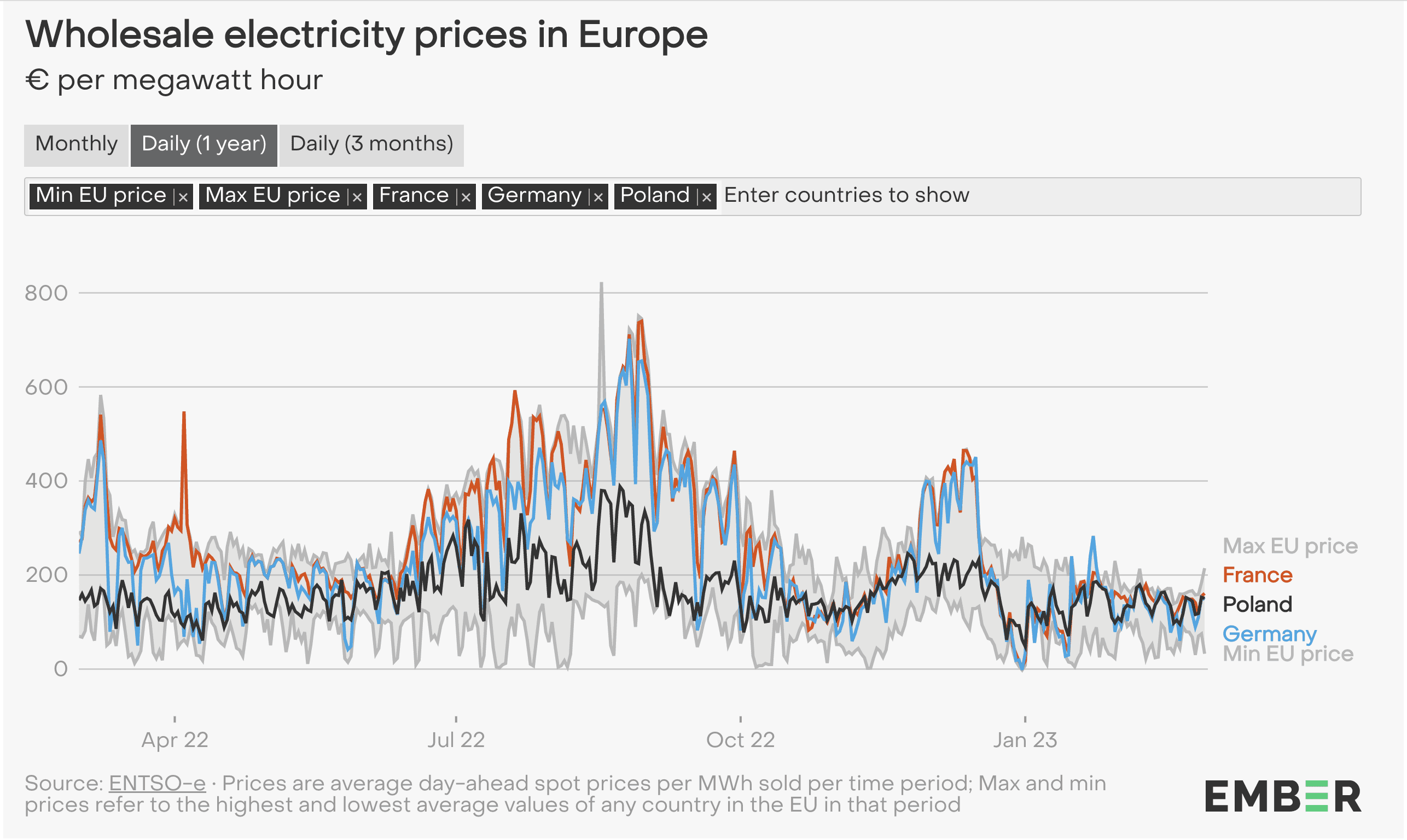

Source: https://ember-climate.org/data/data-tools/europe-power-prices/

For example, take this graph of electricity prices in Europe. The maximum price available per megawatt hour on August 22, 2022 was €823.29, meanwhile somewhere else in Europe had a price as low as €28.70. That is a more than 28x price difference depending on where and when you access electricity. Fuel prices have fluctuated a lot, but certainly not 28x in a single day. Although this data is European, the same holds true for the United States and throughout the rest of the world.

This means where and when you charge could have up to a 28x difference in price, which scaled throughout your fleet can mean the difference between strong profitability and massive losses.

Grid capacity is limited

Your access to electricity depends on how much capacity you have. Depending on where you are on the electricity grid, you may simply not be able to access enough electricity to execute depot charging. It is likely that your depot location was not chosen with grid capacity as a requirement and depending on where you are it could be a huge constraint.

The grid capacity challenge is also a game theory problem. Since there is limited capacity available, if your neighbor decides to build a charge depot as well, your available supply could be cut. This means you need to hedge your bets in your charge strategy. If you rely entirely on depot charging, then supply is suddenly cut, you could be in trouble. That’s why it is critical you build a lean fleet electrification strategy.

Lean fleet electrification strategy: Planning EV charging and route logistics to be flexible and adaptable to changing costs and levels of access to electricity.

How do I start planning my conversion?

The first step to converting your fleet is calculating your charge demand. This is the starting point of a lean electrification strategy. Your charge demand will determine what vehicles are optimal for your fleet, how much battery capacity you need, and how many chargers you need where (your charge supply).

Charge demand: The amount of energy you will need in the future to do all your runs all day, all week, and all year with your fleet. This data will come in the form of kWh (kilowatt hours), the unit of measurement used for electric vehicle charging.

In order to calculate your charge demand, you need to calculate how much energy will be consumed by your vehicles to complete their routes. The easiest and fastest way to do this is through simulation. You can simulate your operations with Evalo by uploading tour files. The simulator uses real-world data to predict energy consumption and provides you with your charge demand. Or you can simulate a single route right now to get an initial idea of what to expect.

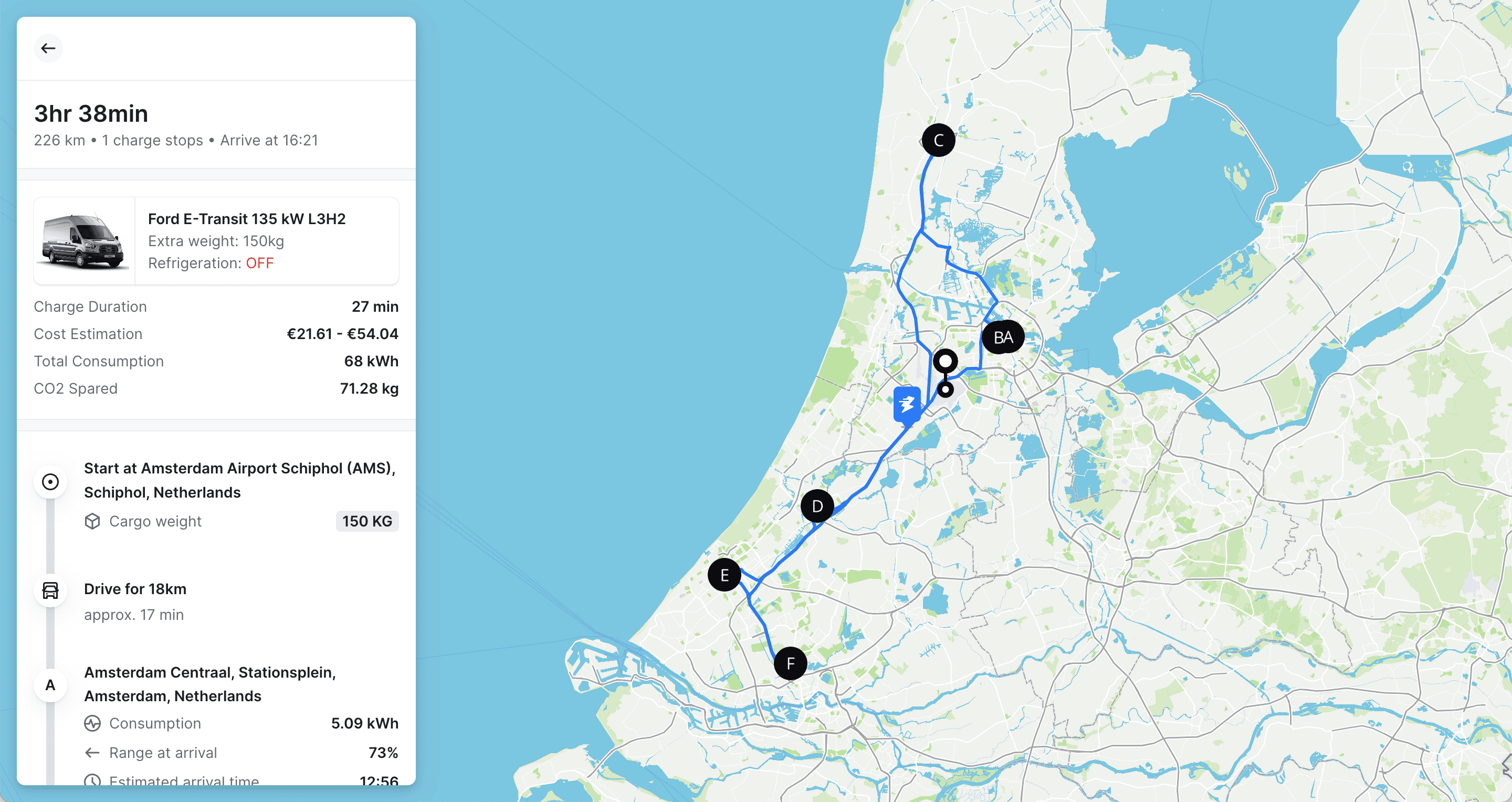

Below is an example of the charge demand for a route around Amsterdam with a charge demand of 68 kWh. If leveraging public infrastructure, the cost estimate is between €21.61 - €54.04.

Charge supply: Your fleet’s charge supply is its access to energy for operating vehicles. This comes in the form of energy availability through charge infrastructure and battery capacity.

Once you have your charge demand, you can use that data to build your plan. This will include planning your charge infrastructure, procuring your vehicles, and preparing your operations for changing schedules. Without first understanding your charge demand, you will be making these decisions blind and it will be hard to predict their impacts until your operations begin. Instead, you want to calculate your charge demand so you can accurately predict the operational and monetary effects on your business.

The key to a successful electric fleet is matching charge-demand with charge-supply. This is the fundamental model you should use when planning your fleet’s electrification. With precise understanding of charge demand, you then want to plan charge supply that matches the needs of your fleet.

But I have EV telematics, isn’t that enough?

You may have your telematics data to get the current SOC (State of Charge) for a trip. This is useful for seeing historical charge demand. However, if your routes are not the same each day, then this doesn’t help you very much.

What you need is future charge demand because you need your vehicles to be mission-ready for their routes tomorrow, not yesterday’s. The best way to calculate this is through simulation, which we will discuss in more depth further on.

How do I plan my EV fleet charging?

Planning charging for your fleet is the cornerstone of your electrification strategy. The EV fleet charging solutions you choose will have a massive impact on your long-term success and must come in stages informed by your predicted charge demand.

The first question is whether or not you have a depot. If yes, you will want to consider a more centralized charge strategy. If not, you will need to build a decentralized strategy.

Centralized vs. decentralized charge strategy

The core of your infrastructure planning comes from your focus on a centralized or decentralized charge strategy. What do these mean?

Centralized charge strategy: Planning charging around a centralized charging hub (depot charging)

Decentralized charge strategy: Planning charging across distributed charging locations

What should I consider with depot charging (centralized strategy)?

Depot charging presents massive opportunities for efficiency, but also comes with challenges and risks to consider.

A huge cost-savings opportunity

It is much cheaper to charge EV fleet vehicles at your depot rather than through public charge infrastructure. Since you will get wholesale energy prices, you can take advantage and reduce your energy costs. If you do have a depot, you should look at maximizing how much charging is done through it.

One approach you might consider is to do exclusively depot charging. However, before committing to this direction, you must consider the following.

Avoid over-investing in charge infrastructure

Build one EV charger for each vehicle then charge them overnight in the depot after a shift. This ensures they are all mission-ready in the morning with fully charged batteries. Right?

This sounds ideal, but it is not the most efficient solution to organize your depot charging. Chargers can be anywhere from $500-2000 each. Scale this up to hundreds or thousands of vehicles and that could be millions in unnecessary expense.

Depending on the routes of each vehicle, many vehicles may not require a charge every day. This means that you likely don’t need a charger for each vehicle. You should calculate how often each vehicle will require a charge and build the number of chargers necessary to achieve this, adding some extra for redundancy. This calculated approach will save you huge on CapEx.

Depot charging limits you to short, predictable routes

By only charging at the depot, you are limited to single charge routes; routes that you know for certain can be completed within a single charge of the battery. Depending on your use case, this could be fine, or it could be completely unfeasible.

If you know your routes vary day-by-day and fall outside the range of most vehicles, then you should plan some external charging options as well. If you run predictable routes within the range of a single charge, then charging exclusively at your depot makes sense.

Avoid over-investing in battery capacity

Since you are limited to predictable routes by only charging at the depot, you will likely end up investing in more battery capacity than you really need. Batteries are the most expensive part of an EV, so this could be the difference of 10’s of thousands of dollars per vehicle if you are purchasing battery options beyond than your needs. At scale, this could be the difference of millions.

Instead, you should calculate your charge demand first and use this data to invest in battery pack sizes that are appropriate for your demand. This will save you on CapEx while ensuring your operations are efficient and reliable.

What should I consider with external charging (decentralized strategy)?

If you don’t have a depot, you will likely need a more decentralized charge strategy. You will have to charge your vehicles en-route through public charge infrastructure, build your own infrastructure in strategic locations, or partner with another company to build or share a charge hub.

Freedom of operations

The benefit of decentralized charging is the freedom it provides to your operations vs. depot charging. It enables longer and more complex routes and can open up efficiencies by optimizing for factors like charge curves as described earlier in the article. For fleets with long and highly unpredictable routes, external charging is a must.

Logistical challenges

A downside is the logistical challenges that come with decentralized charging. You need to identify the most strategic locations for your charging. This can be very difficult, but can be done strategically if you understand your charge demand.

The best way to start planning your external charging plan is to map out your charge demand through simulation. This will show you where you will require electricity and how much, based on your real routes. You can use this data to identify the areas you need charge infrastructure and how many chargers you will need.

Leverage bargaining power for energy prices

As a fleet with a large number of vehicles, you have bargaining power to negotiate a good price with charging partners. Unlike individual consumers who are forced to pay the retail price for charging, you have the advantage of volume. You should use the size of your fleet to negotiate strong discounts from charging partners. This will go a long way in reducing your variable costs and contribute to healthy margins.

Which electric fleet vehicles should I buy?

This is of course a fundamental question for electrifying your fleet. There are lots of commercial electric vehicles available on the market now; everything from small, large, and mid-sized vans, to buses, and long-haul trucks. Just about every category of commercial vehicle is now available in electric models.

Fortunately, this growing abundance of options means you likely don’t have to sacrifice much in the way of physical needs like interior details, payload, space, or layout. You need vehicles that match these needs, but with an electric fleet, your most critical decision is battery. Your vehicles must provide the appropriate charge supply.

Within each model, there are multiple options for battery size that have significant impacts on the range of your vehicle, therefore impacting how often and how long you will need to charge that vehicle on its routes.

It may seem like an obvious choice to choose the largest battery capacity available, but you will quickly see significant price differences due to the high cost of batteries. The more range the better for sure, but depending on your charge demand requirements, you might be able to save big on battery costs. One battery size option up can be thousands if not ten’s of thousands. Scale this added cost to your whole fleet and that could be the difference of millions. This is why it’s important you evaluate the appropriate level of charge supply, not necessarily the maximum level of charge supply.

You should buy vehicles with battery capacity that matches your charge demand. By simulating different battery capacity and charge supply scenarios, you can understand the costs of different choices as well as their impacts on your operations. This will allow you to choose vehicles that are most cost-effective for your fleet while still ensuring you can achieve your mission every day.

How do I optimize OpEx in an electrified fleet?

Your fleet’s TCO is impacted hugely by your variable costs of refueling. The same holds true for electric fleets, but instead of fuel costs you have energy costs.

Managing energy costs brings different challenges from managing fuel costs. First of all, as discussed earlier, energy costs are much more volatile than fuel. This is a key difference for operating electric fleet vehicles, especially if you will make use of depot charging.

In order to optimize your fleet’s energy costs, you must plan charging on off-peak times as much as possible and ensure you are accessing charging stations with the lowest available costs. By planning to charge around the cheapest times for energy, you can dramatically lower your variable costs and maximize your margins.

You will also want to optimize your depot charging with smart charging stations. Smart charging solutions control the speed and timing of charging to help optimize peak and off-peak and balance the grid. This technology will help you take advantage of charge costs with less manual intervention.

Even with external charging, one charge provider, or eMSP (e-mobility service provider), could charge 50% more than another across the street, and it often isn’t easy to tell. As mentioned previously, you should also use your bargaining power to negotiate better pricing from charge partners to ensure low costs and price consistency.

How do I calculate my charge demand to start making decisions?

You can build a lean, cost-effective, and tested fleet electrification plan through simulation. By simulating your operations, you can see what your fleet could look like once you start converting to electric vehicles. You will be able to calculate your charge demand, which will drive your decisions around battery capacity for vehicle procurement, how many chargers you will need where, and what your charge schedules will look like.

By developing all of these plans around a centralized source of data, you can ensure that all of your decisions are aligned and optimized for TCO and profitability.

Electrification is so much more than procurement of vehicles and chargers. By starting with data, you will be able to build a comprehensive plan that accounts for all of the complex aspects that will impact your fleet through its transition to electric.

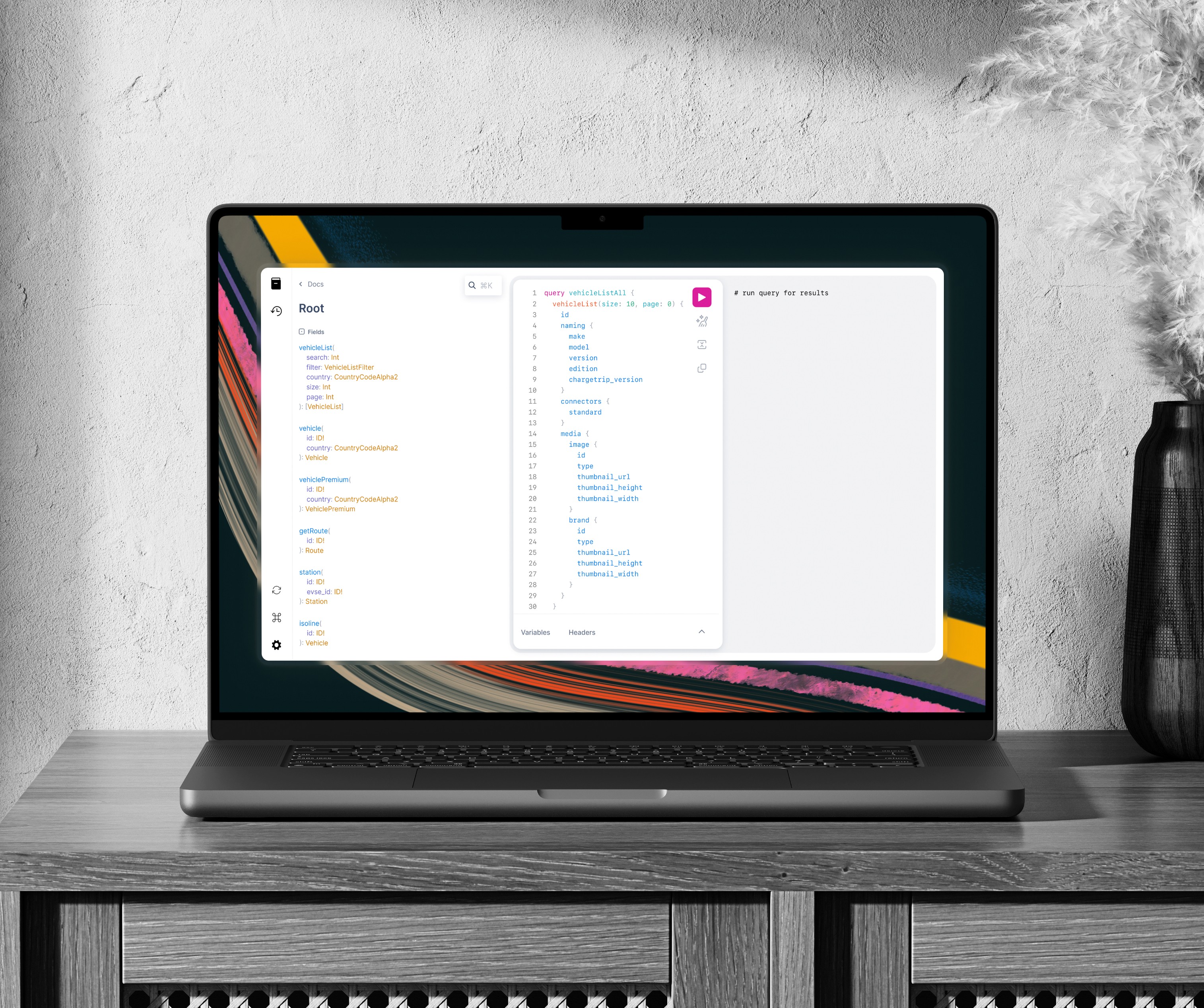

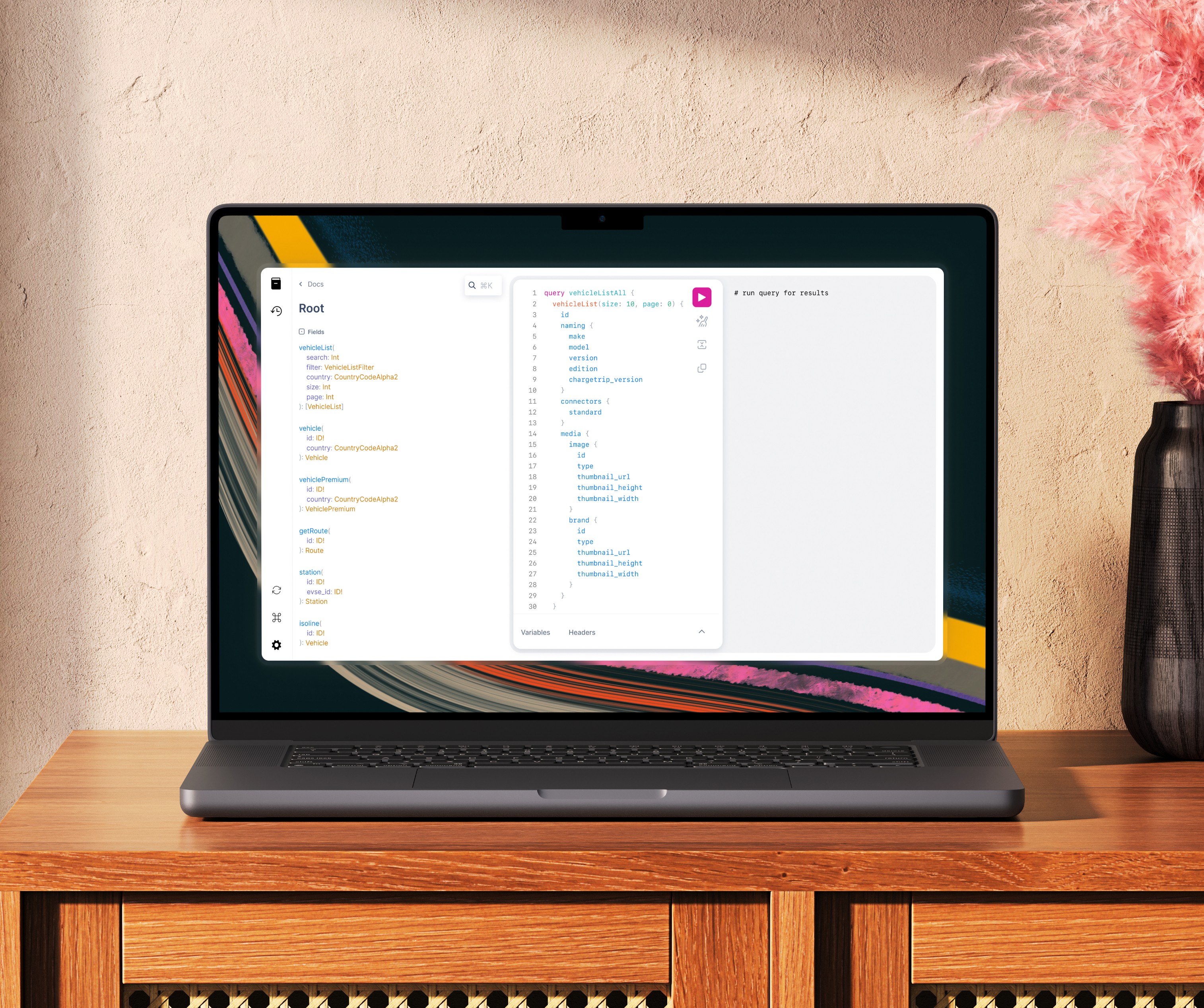

Evalo electric fleet simulation

You can use Evalo by Chargetrip to map out your charge demand and build a full blueprint for your fleet electrification.

By simply uploading tour files, you can get valuable data including:

Your fleet’s charge demand

What vehicles to buy with what battery configurations

Where and for how long to charge vehicles

Charge infrastructure planning recommendations

Charge cost estimations

CO2e emission profiles and savings

Simulate a route with Evalo

Simulate routes one at a time for free with Evalo. Just input route details, select a vehicle model, and click simulate.

Click the link to see what routes look like with EVs.